Darcy–Weisbach equation

In fluid dynamics, the Darcy–Weisbach equation is a phenomenological equation, which relates the head loss — or pressure loss — due to friction along a given length of pipe to the average velocity of the fluid flow. The equation is named after Henry Darcy and Julius Weisbach.

The Darcy–Weisbach equation contains a dimensionless friction factor, known as the Darcy friction factor. This is also called the Darcy–Weisbach friction factor or Moody friction factor. The Darcy friction factor is four times the Fanning friction factor, with which it should not be confused.[1]

Contents |

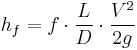

Head loss form

Head loss can be calculated with

where

- hf is the head loss due to friction (SI units: m);

- L is the length of the pipe (m);

- D is the hydraulic diameter of the pipe (for a pipe of circular section, this equals the internal diameter of the pipe) (m);

- V is the average velocity of the fluid flow, equal to the volumetric flow rate per unit cross-sectional wetted area (m/s);

- g is the local acceleration due to gravity (m/s2);

- f is a dimensionless coefficient called the Darcy friction factor. It can be found from a Moody diagram or more precisely by solving the Colebrook equation.

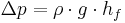

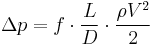

Pressure loss form

Given that the head loss hf expresses the pressure loss Δp as the height of a column of fluid,

where ρ is the density of the fluid, the Darcy–Weisbach equation can also be written in terms of pressure loss:

where the pressure loss due to friction Δp (units: Pa or kg/ms2) is a function of:

- the ratio of the length to diameter of the pipe, L/D;

- the density of the fluid, ρ (kg/m3);

- the mean velocity of the flow, V (m/s), as defined above;

- a (dimensionless) coefficient of laminar, or turbulent flow, f.

Since the pressure loss equation can be derived from the head loss equation by multiplying each side by ρ and g.

Darcy friction factor

- See also Darcy friction factor formulae

The friction factor f or flow coefficient λ is not a constant and depends on the parameters of the pipe and the velocity of the fluid flow, but it is known to high accuracy within certain flow regimes. It may be evaluated for given conditions by the use of various empirical or theoretical relations, or it may be obtained from published charts. These charts are often referred to as Moody diagrams, after L. F. Moody, and hence the factor itself is sometimes called the Moody friction factor. It is also sometimes called the Blasius friction factor, after the approximate formula he proposed.

For laminar (slow) flows, it is a consequence of Poiseuille's law that λ = 64/Re, where Re is the Reynolds number calculated substituting for the characteristic length the hydraulic diameter of the pipe, which equals the inside diameter for circular pipe geometries.

For turbulent flow, methods for finding the friction factor f include using a diagram such as the Moody chart; or solving equations such as the Colebrook–White equation, or the Swamee–Jain equation. While the diagram and Colebrook–White equation are iterative methods, the Swamee–Jain equation allows f to be found directly for full flow in a circular pipe.

Confusion with the Fanning friction factor

The Darcy–Weisbach friction factor is 4 times larger than the Fanning friction factor, so attention must be paid to note which one of these is meant in any "friction factor" chart or equation being used. Of the two, the Darcy–Weisbach factor is more commonly used by civil and mechanical engineers, and the Fanning factor by chemical engineers, but care should be taken to identify the correct factor regardless of the source of the chart or formula.

Most charts or tables indicate the type of friction factor, or at least provide the formula for the friction factor with laminar flow. If the formula for laminar flow is f = 16/Re, it's the Fanning factor, and if the formula for laminar flow is f = 64/Re, it's the Darcy–Weisbach factor.

Which friction factor is plotted in a Moody diagram may be determined by inspection if the publisher did not include the formula described above:

- Observe the value of the friction factor for laminar flow at a Reynolds number of 1000.

- If the value of the friction factor is 0.064, then the Darcy friction factor is plotted in the Moody diagram. Note that the nonzero digits in 0.064 are the numerator in the formula for the laminar Darcy friction factor: f = 64/Re.

- If the value of the friction factor is 0.016, then the Fanning friction factor is plotted in the Moody diagram. Note that the nonzero digits in 0.016 are the numerator in the formula for the laminar Fanning friction factor: f = 16/Re.

The procedure above is similar for any available Reynolds number that is an integral power of ten. It is not necessary to remember the value 1000 for this procedure – only that an integral power of ten is of interest for this purpose.

History

Historically this equation arose as a variant on the Prony equation; this variant was developed by Henry Darcy of France, and further refined into the form used today by Julius Weisbach of Saxony in 1845. Initially, data on the variation of f with velocity was lacking, so the Darcy–Weisbach equation was outperformed at first by the empirical Prony equation in many cases. In later years it was eschewed in many special-case situations in favor of a variety of empirical equations valid only for certain flow regimes, notably the Hazen–Williams equation or the Manning equation, most of which were significantly easier to use in calculations. However, since the advent of the calculator, ease of calculation is no longer a major issue, and so the Darcy–Weisbach equation's generality has made it the preferred one.

Derivation

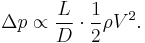

The Darcy–Weisbach equation is a phenomenological formula obtainable by dimensional analysis.

Away from the ends of the pipe, the characteristics of the flow are independent of the position along the pipe. The key quantities are then the pressure drop along the pipe per unit length, Δp/L, and the volumetric flow rate. The flow rate can be converted to an average velocity V by dividing by the wetted area of the flow (which equals the cross-sectional area of the pipe if the pipe is full of fluid).

Pressure has dimensions of energy per unit volume. Therefore, the pressure drop between two points must be proportional to (1/2)ρV2, which has the same dimensions as it resembles (see below) the expression for the kinetic energy per unit volume. We also know that pressure must be proportional to the length of the pipe between the two points L as the pressure drop per unit length is a constant. To turn the relationship into a proportionality coefficient of dimensionless quantity we can divide by the hydraulic diameter of the pipe, D, which is also constant along the pipe. Therefore,

The proportionality coefficient is the dimensionless "Darcy friction factor" or "flow coefficient". This dimensionless coefficient will be a combination of geometric factors such as π, the Reynolds number and (outside the laminar regime) the relative roughness of the pipe (the ratio of the roughness height to the hydraulic diameter).

Note that (1/2)ρV2 is not the kinetic energy of the fluid per unit volume, for the following reasons. Even in the case of laminar flow, where all the flow lines are parallel to the length of the pipe, the velocity of the fluid on the inner surface of the pipe is zero due to viscosity, and the velocity in the center of the pipe must therefore be larger than the average velocity obtained by dividing the volumetric flow rate by the wet area. The average kinetic energy then involves the mean-square velocity, which always exceeds the square of the mean velocity. In the case of turbulent flow, the fluid acquires random velocity components in all directions, including perpendicular to the length of the pipe, and thus turbulence contributes to the kinetic energy per unit volume but not to the average lengthwise velocity of the fluid.

Practical applications

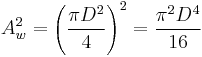

In hydraulic engineering applications, it is often desirable to express the head loss in terms of volumetric flow rate in the pipe. For this, it is necessary to substitute the following into the original head loss form of the Darcy–Weisbach equation

where

- V is, as above, the average velocity of the fluid flow, equal to the volumetric flow rate per unit cross-sectional wetted area;

- Q is the volumetric flow rate;

- Aw is the cross-sectional wetted area;

For the general case of an arbitrarily-full pipe, the value of Aw will not be immediately known, being an implicit function of pipe slope, cross-sectional shape, flow rate and other variables. If, however, the pipe is assumed to be full flowing and of circular cross-section, as is common in practical scenarios, then

where D is the diameter of the pipe

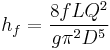

Substituting these results into the original formulation yields the final equation for head loss in terms of volumetric flow rate in a full-flowing circular pipe

where all symbols are defined as above.

See also

References

Further reading

- De Nevers (1970), Fluid Mechanics, Addison–Wesley, ISBN 0-201-01497-1

- Shah, R. K.; London, A. L. (1978), "Laminar Flow Forced Convection in Ducts", Supplement 1 to Advances in Heat Transfer, New York: Academic

- Rohsenhow, W. M.; Hartnett, J. P.; Ganić, E. N. (1985), Handbook of Heat Transfer Fundamentals (2nd ed.), McGraw–Hill Book Company, ISBN 007053554X